Injection moulding made simple. Without the huge tooling costs.

At JC Moulding we make injection moulding easy and cost-effective.

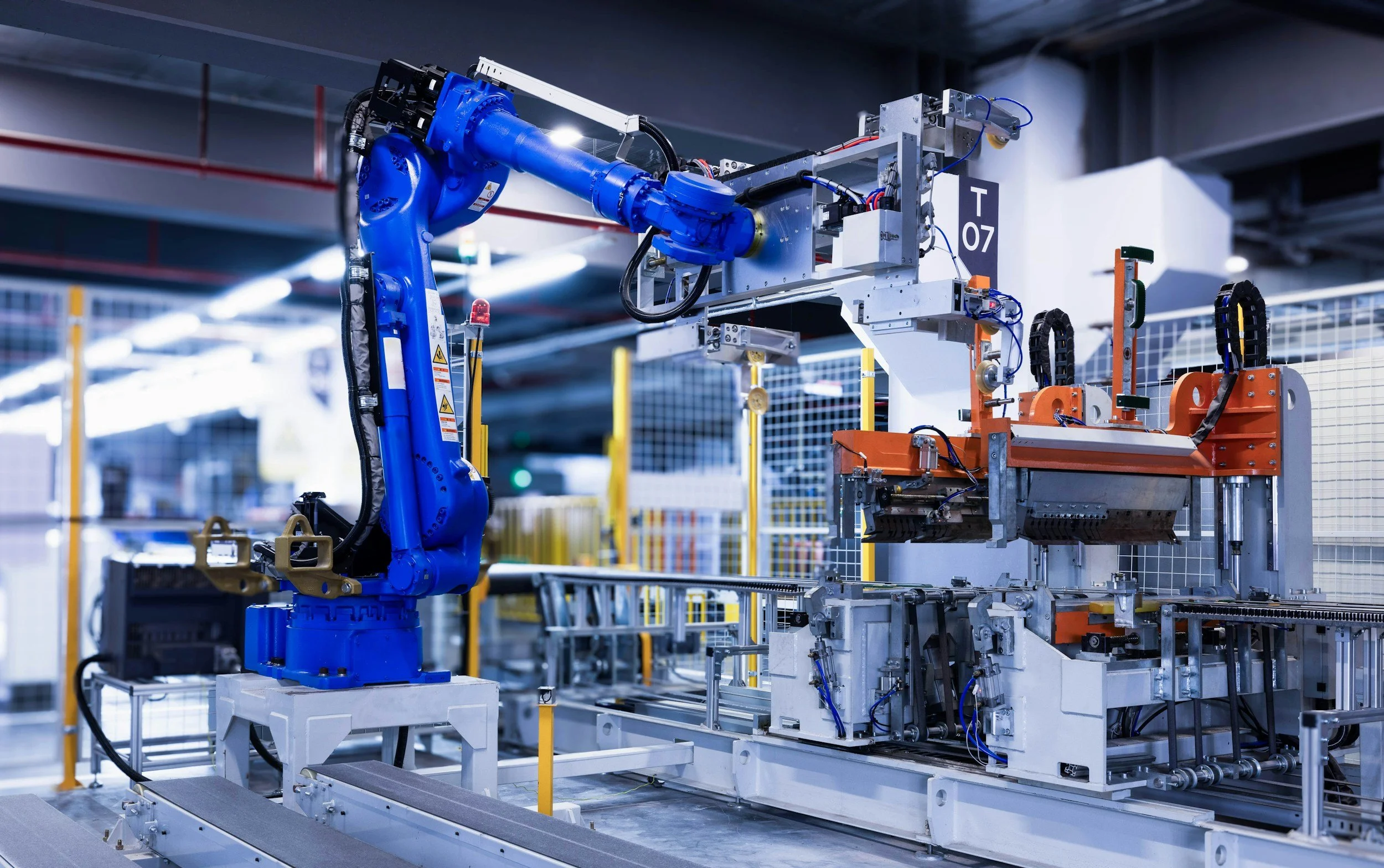

We deliver end-to-end plastic injection moulding solutions that take your project from concept to completion. Backed by decades of expertise and a commitment to innovation, we deliver scalable, high-quality manufacturing services to clients across a diverse range of industries. Our low-cost tooling approach removes the traditional barriers of high upfront investment, enabling businesses to access injection moulding faster, easier, and more cost-effectively, without compromising on quality or precision.

Precision Moulding, Smarter Costs

For over 30 years we have been advancing prototype tooling methods to deliver full production runs at a fraction of the cost of legacy practices.

During this time, our team of mechanical and industrial engineers, tooling designers, product designers, and material experts have been refining our method and approach.

We design, manufacture, repair, and maintain all tooling, on our 2 acre site in South Wales, and with ongoing investment in our 3,000 sqm facility, we boast an extensive range of state-of-the-art tooling and moulding machinery and equipment, operated by an experienced and dedicated team of over 50 staff.

Key Benefits

Lower Costs

Our unique approach to tooling lowers overall project costs and makes injection moulding more cost-effective.

Turn-Key Solution

With in-house toolmaking, rapid prototyping, and a fully equipped machine range, we minimise labour time and streamline every stage of production, providing quicker turnaround from initial samples to full-scale manufacturing.

Lifetime Care

We don’t just manufacture our tooling in house; we stand behind it for life. Every tool comes with our lifetime guarantee, giving you confidence that your investment is protected and your production will remain reliable for years to come.

Rapid Delivery

By managing toolmaking, moulding, and logistics under one roof, we significantly reduce delivery times. We minimise labour time and streamline every stage of production, ensuring your components move seamlessly from production to market without unnecessary delays.

Making Injection Moulding Accessible

Low-Cost Tooling, Flexible Volumes

We make injection moulding accessible without the need for heavy upfront costs. Our low-cost tooling removes the usual barrier, no MOQ’s are viable, with practical batch sizes such as 250, 500, 1,000, and 5,000.

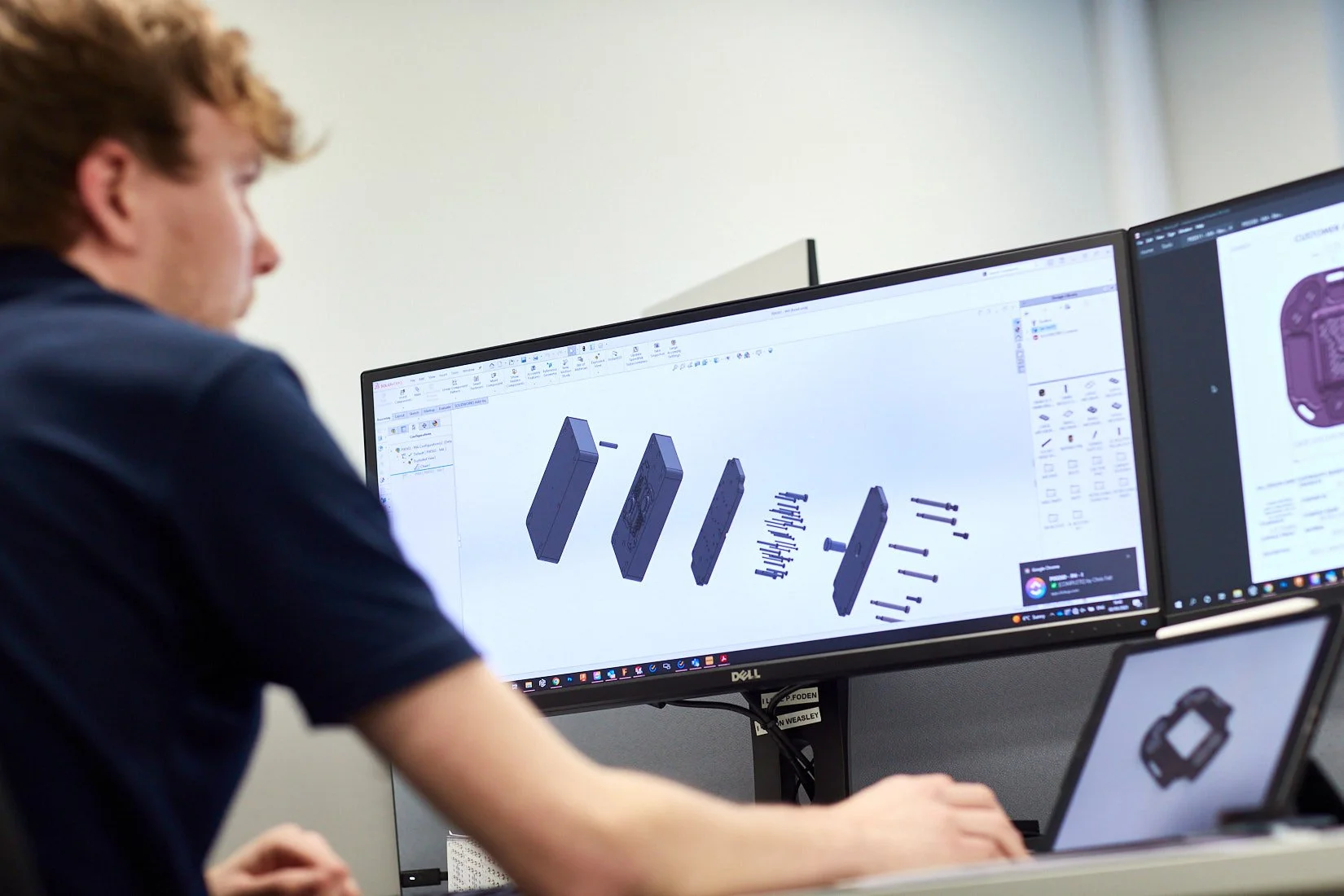

In-House CNC Tooling & Rapid Prototyping

All mould tools are made in our fully equipped CNC toolroom in South Wales. We design, manufacture, maintain and repair on-site. With rapid prototyping, you get some of the shortest sample lead times, tighter quality control and predictable costs.

End-to-End Support

We partner with manufacturers, engineers and product designers to deliver precision-moulded components and tooling. From early design support to final assembly, we manage every stage in-house to ensure quality, efficiency, and peace of mind.

Our Services

At JC Moulding, we start every partnership with innovative ideas, collaborating with top brands across various industries. Whether you're starting a new business, turning a passion or hobby into a tangible product, or developing a unique and creative project, we are dedicated to providing high-quality, precision-engineered injection-moulded components. We design and manufacture each product carefully to meet the precise needs of each sector, guaranteeing reliability and excellence throughout the process.

-

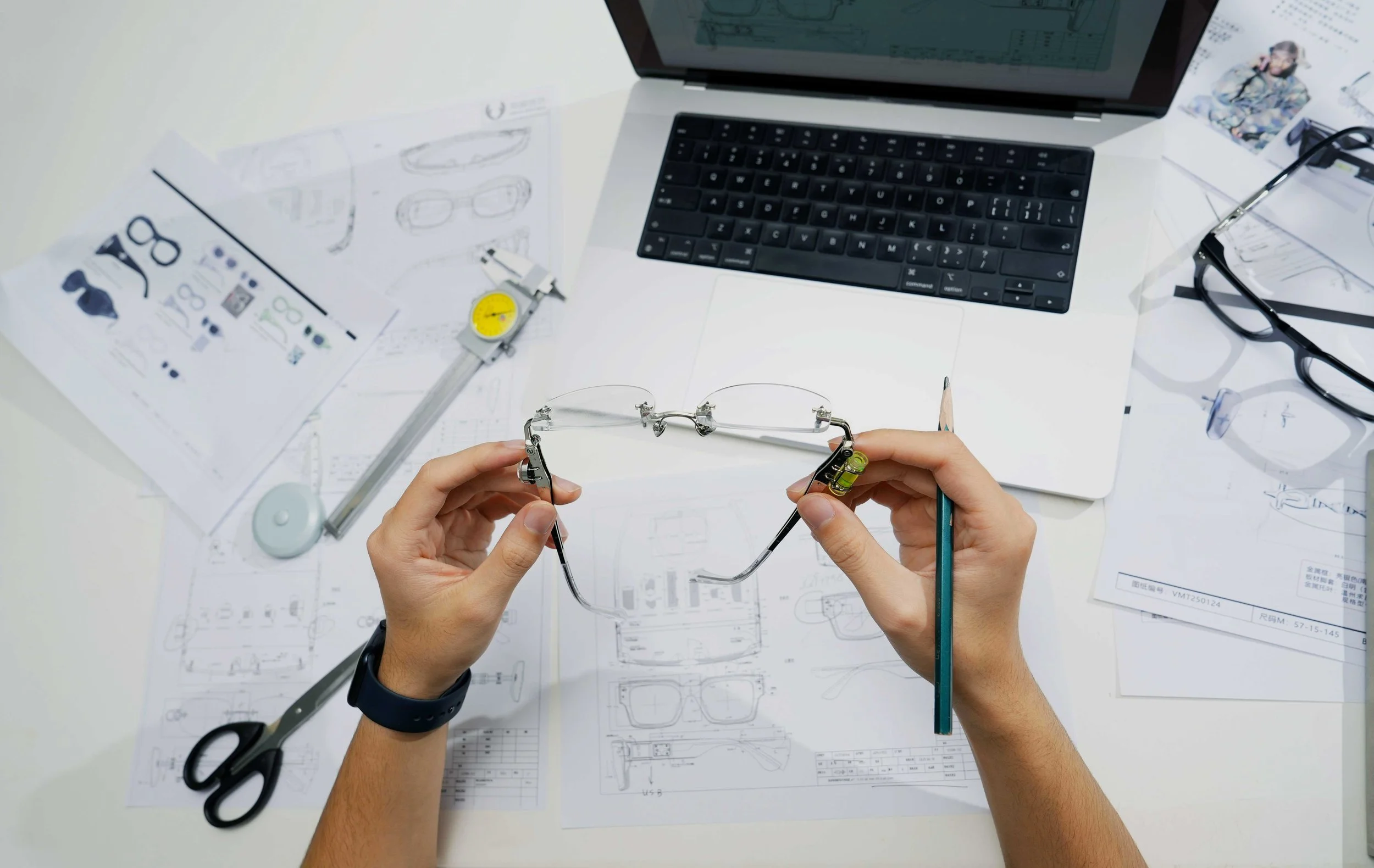

We design and manufacture our custom injection moulding tools in house. Designed and built for our unique process, we utilise CAD/CAM and rapid prototyping to deliver precision and speed.

-

With moulding machines from 25 to 250 tonnes, we produce components up to 600g, delivering consistent quality from small batches to full-scale production.

-

Our 3D printing and FDM prototyping services deliver accurate, structural parts that replicate the final product, helping you refine designs quickly and confidently.

-

Using advanced equipment, we provide comprehensive mechanical testing, from tensile strength to impact resistance, ensuring your components meet performance and durability standards.

-

Our in-house design team offers full product design, transforming everything from rough sketches to detailed concepts into tailored, production-ready solutions.

-

We provide efficient assembly and packaging to deliver market-ready products.

-

We offer secure warehousing, on-demand stock management, and next-day delivery within the UK. Keeping your products safe, accessible, and ready to ship.

Sectors We Serve

At JC Moulding, we start every partnership with innovative ideas, collaborating with top brands across various industries. Whether you're starting a new business, turning a passion or hobby into a tangible product, or developing a unique and creative project, we are dedicated to providing high-quality, precision-engineered injection-moulded components. We design and manufacture each product carefully to meet the precise needs of each sector, guaranteeing reliability and excellence throughout the process.

-

Industrial sectors rely on injection moulding for precision-engineered components that deliver long-term durability and cost efficiency, with tooling designed to last for years and scalable production that ensures consistent quality under demanding conditions.

-

Agricultural sectors depend on injection moulding to produce robust, weather-resistant components that deliver long-term reliability, with tooling designed for years of service and scalable production that ensures consistent quality for demanding outdoor environments.

-

The construction sector relies on injection moulding to deliver high-strength, precision components that withstand harsh environments for years, offering cost-effective scalability and unique design flexibility for complex structural and safety applications.

-

The furniture sector relies on injection moulding to create stylish, ergonomic components that deliver long-lasting performance, with tooling designed for years of service and the flexibility to produce custom finishes and colours at scale.

-

Emergency services rely on injection moulding to produce rugged, precision components that ensure safety and reliability in critical situations, with tooling built for years of service and unique design flexibility to meet strict performance standards.

-

Product designers turn to injection moulding to achieve precise, durable, and highly customisable components that deliver both aesthetic excellence and longlasting performance.

-

Hospitality and retail sectors rely on injection moulding to create durable, custom-designed fixtures and display components that enhance brand experience, with tooling built for years of service and unique flexibility in colour, finish, and scalability.

-

The leisure sector relies on injection moulding to create durable, lightweight components that enhance user experience, with tooling designed for years of service and unique flexibility in colour, texture, and custom shapes for recreational environments.

Case Studies

Have a question?

For more information about JC Moulding, our processes, and the range of services we offer, please visit our FAQs page. There, you will find straightforward and detailed answers to commonly asked questions regarding tooling, moulding, prototyping, and logistics. Whether you're exploring a new project, evaluating production options, or seeking general guidance, our FAQs are designed to provide the reassurance you need.

Our vision

With over 30 years of experience, JC Moulding specialises in flexible production runs from 1 to 100,000 parts. Our low-cost tooling system makes injection moulding accessible and affordable, reducing upfront investment and allowing customers to scale seamlessly from prototype to full production.

Interested in

working together?

To discuss your project and obtain an estimated tooling cost, please contact us on 01495 315631 or complete our contact form. A member of our team will respond within 24 hours to guide you through the next steps.